PROJECTS

Supply chain traceability system

- Enterprise, Logistics

The use case

Vietnam is a developing country with a population of 100 million. Recently, food safety got major focus in the government. Since most of the food supply chain doesn’t have cold chain infrastructure (refrigerated transport vehicles and storages), it became important to monitor the freshness of food products to ensure consumers that their food is still safe to eat.

This demand was implemented in the local regulation, but required an IT system, which enables farms to report harvest and transports, slaughterhouses to report slaughterings, and downstream participants (wholesalers, retailers) to report when they received and sent a transport. To track the batches of products efficiently, a QR code based batch/LOT identification system had to be implemented.

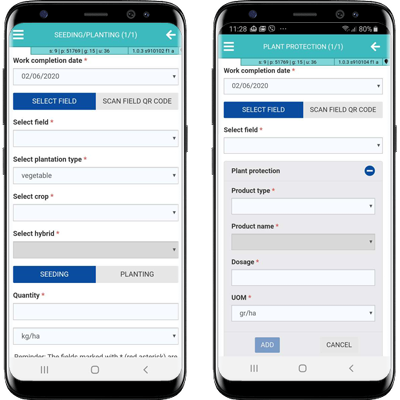

Although most supply chain participants, especially smallholder farms don’t have any legacy system for farm management, almost all of them have mobile phones with internet access, so the basis of the data collection needed to be a mobile app.

The solution

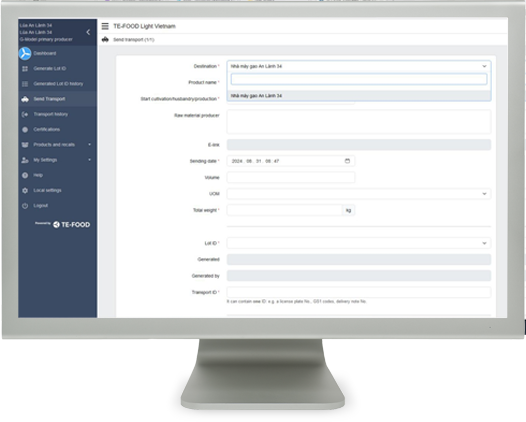

Our company had been working with a german company, TE-FOOD GmbH to develop a software solution which contains

- a backend for the traceability program manager, where the manufacturing and distribution of QR code based identification materials (plastic security seals, paper based labels, paper bags) are managed. This includes a serial engine to generate the unique codes in various formats.

- an Android/iOS mobile app, which enables supply chain participants from farms to retail to register key events (harvesting, sending or receiving transports, aggregation of batches, etc.).

- an API which enables larger participants (e.g. retail chains, food producers) to send traceability data from their legacy systems.

- a web content generator module, which automatically generates the traceability journal into HTML pages, which can be visited by consumers, when they scan the QR code on the retail products.

- a robust reporting module, which regularly generates over 200 different lists and statistics for government bodies and supply chain participants.

- integration to price checker terminals at supermarkets, which can also display the batch level traceability information to consumers.

- a product recall module enables supply chain participants to report contamination issues, and enables the automatic recall of all batches, which originates from the contaminated batch.

The result

The solution is used by over 6000 companies in Southern Vietnam, including all major retail chains. The system tracks pig meat, eggs and chicken meat form farm to table, generating an average 150-200 000 business transactions each day.